Website intended for professional users with knowledge or professional experience that enable the use of SmartFlags for their intended purpose.

I declare that:

Website intended for professional users with knowledge or professional experience that enable the use of SmartFlags for their intended purpose.

I declare that:

A technological breakthrough in full

digital protocol for IOS all-on-x cases

(01.) Idea

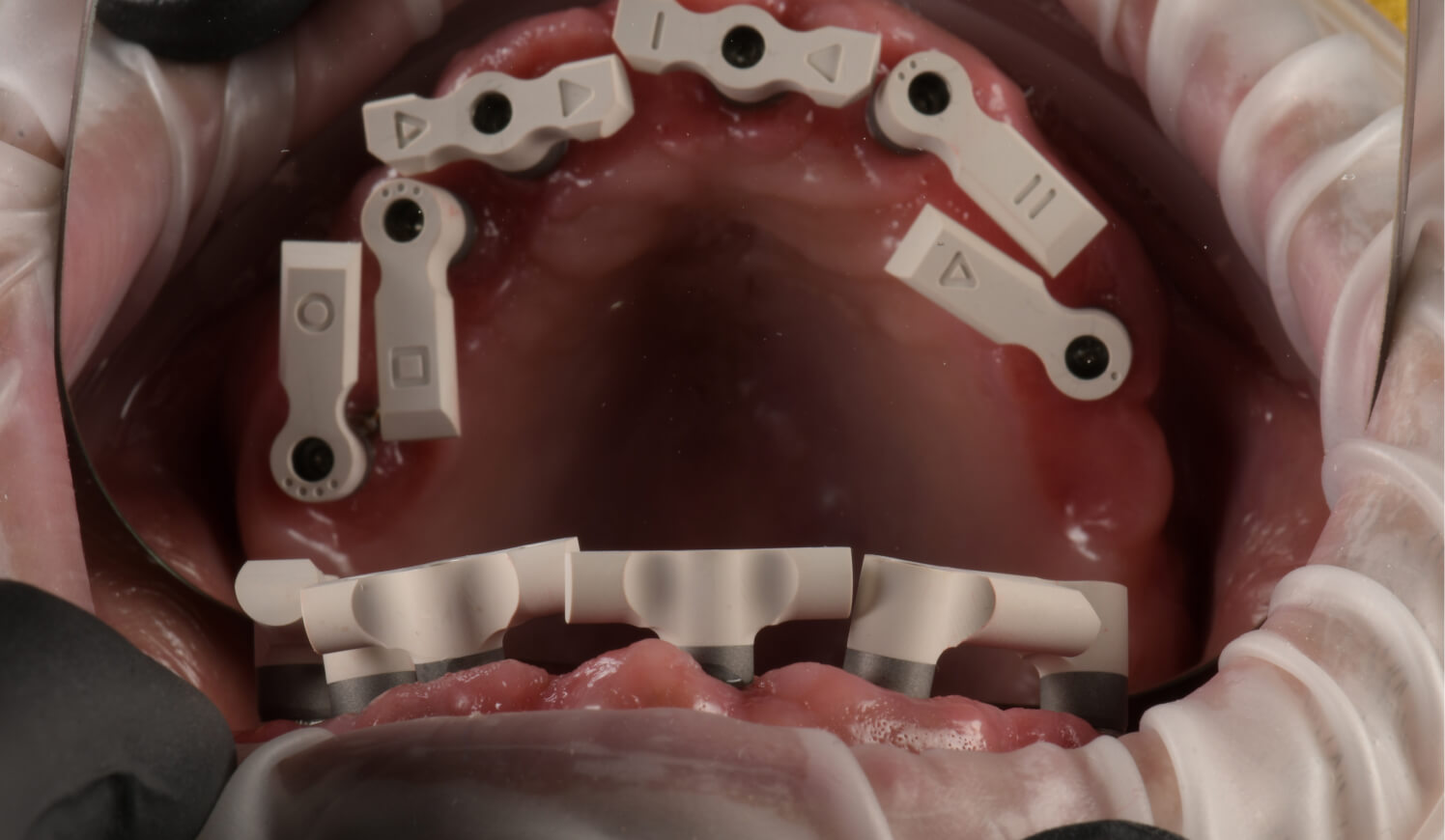

See how an intraoral scanning using SmartFlag accurately reflects the situation in the patient's mouth.

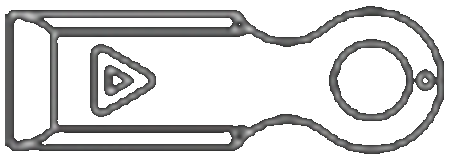

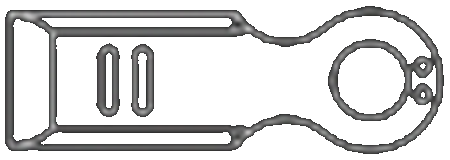

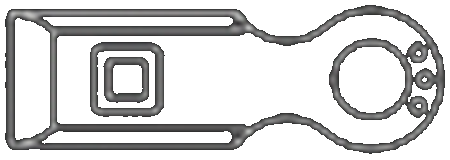

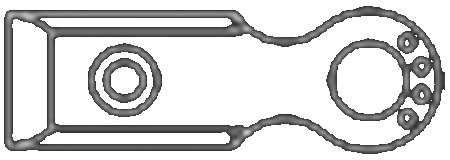

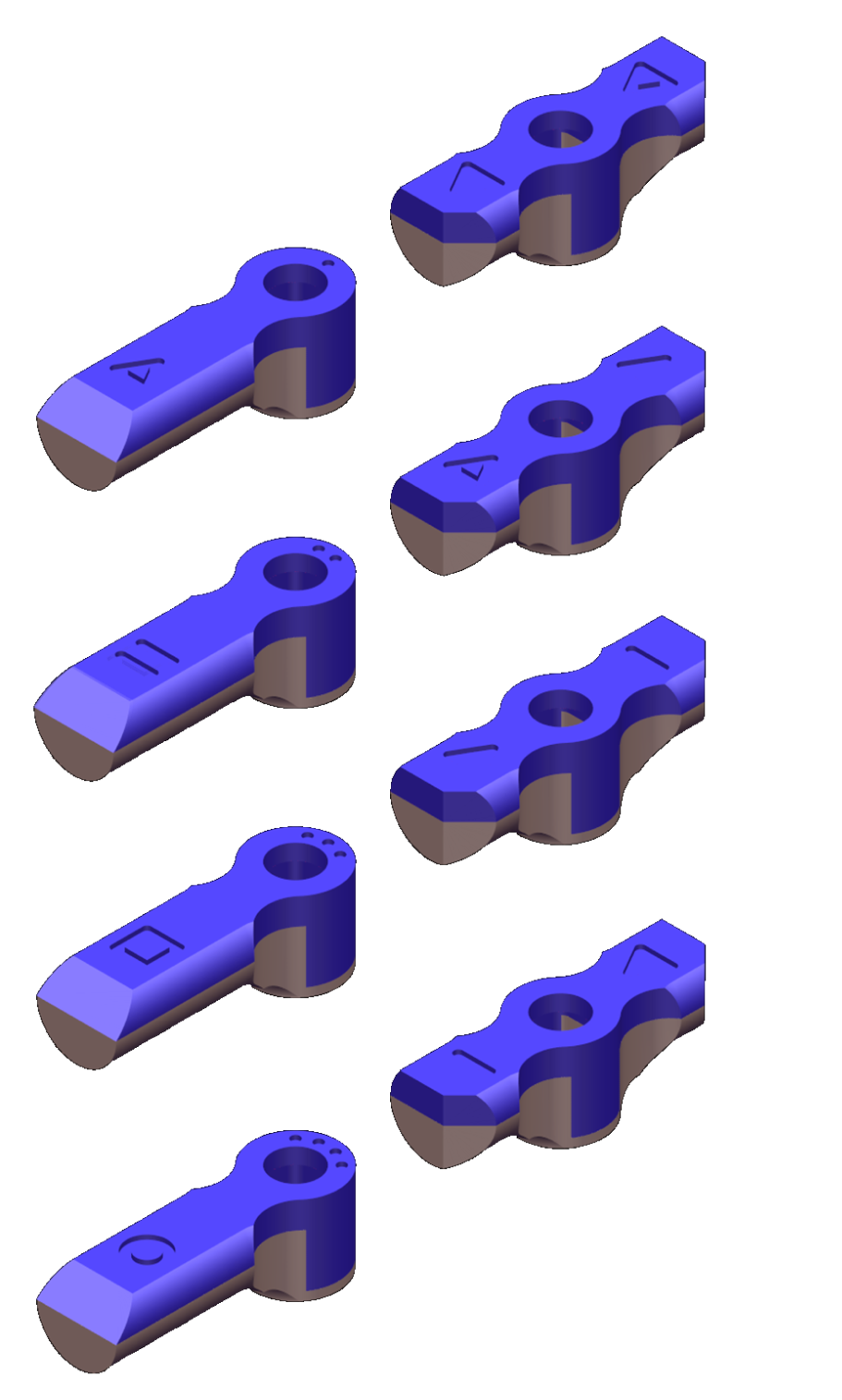

(02.) Types of SmartFlags

Multiunit Level

Multiunit Level

Implant Level

Available soonSet includes 8 pieces of Scanbody SmartFlag by APOLLO® with individual markings:

A

B

C

D

E

F

G

H

(03.) Features

(01.)

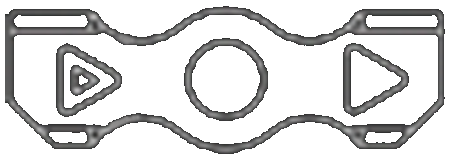

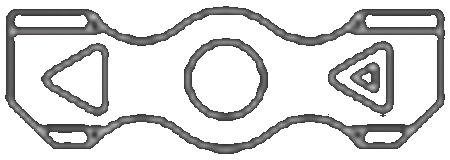

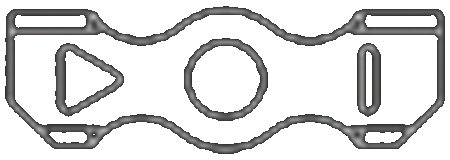

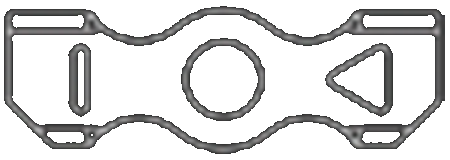

The shape of SmartFlag solids and their two types of 1- or 2-wing allow for optimal filling of spaces between implants.

(02.)

The optimal height of SmartFlag, different for the scanbody from the implant and multi-unit level, facilitates clinical work.

(03.)

Characteristic geometry and large reference area ensures precise matching of CAD libraries.

(04.)

Unique marks on each scanbody allow for a smooth scanning process, without the need to "block" previously scanned scanbodies.

(05.)

Clear markings allow for easy identification of a compatible implant system.

(06.)

Side cuts show the implant axis.

(07.)

The anti-reflective surface of the entire scanbody, provided by the medical polymer PEEK, facilitates the scanning process.

(08.)

Titanium provides a tight connection with the implant.

(09.)

Scanbody durability, up to 100 sterilization cycles, ensured by high quality medical materials

(10.)

Certified medical materials titanium alloy Ti6Al4V ELI

Features

(04.) Scanners and scanning

From now on, you can use the full capabilities of your scanner for all-on-x implant cases

View user manual

01

(1 or 2 wings) – match their type to the space between the implants

02

on a flat reference surface, pay special attention to this when using different implant platforms or different implant systems

03

if clinical conditions allow

04

(while maintaining the smallest distance between SmartFlag) – check with dental floss whether the appropriate distances are maintained – the floss should loosely pass between SmartFlag

05

dedicated to the implant system used – screwing force 15 Ncm

06

to confirm the correct placing of scanbody

Settings

The unique shape with a large reference surface of the SmartFlag by APOLLO solid, ensures a smooth

scanning process, giving confidence in reproducing the implant position.

01

Do a smooth motion so that they are all scanned, and return by scanning with a sweeping motion

02

cannot touch the Smartflag

03

and do not lose the SmartFlag view from scanner registration field

04

when switching from one SmartFlag to another – make sure that the scanner tip covered both SmartFlag in the registration field at the same time

05

start the process again from the place with the registered characteristic surface.

06

reference surfaces during the scanning process

07

of the scanning process to your laboratory/milling center

Case no. 1

Protocol

Required components

Scanbody SmartFlag by APOLLO

Multi Titanium Base

Multi Titanium Base multiSHIFT36°

CAD/CAM Libraries

Case no. 2

Required components

Scanbody SmartFlag by APOLLO

Multi Titanium Base

Multi Titanium Base multiSHIFT36°

One Lock Digital Analog - in case of using printed model

CAD/CAM Libraries

Case no. 3

Required components

Scanbody SmartFlag by APOLLO

One Lock Digital Analog - in case of using printed model

CAD/CAM Libraries

Case no. 4

Required components

Scanbody SmartFlag by APOLLO

Multi Titanium Base

Multi Titanium Base multiSHIFT36°

One Lock Digital Analog - in case of using printed model

CAD/CAM Libraries

Case no. 5

Required components

Scanbody SmartFlag by APOLLO

One Lock Digital Analog - in case of using printed model

CAD/CAM Libraries

Case no. 6

Required components

Scanbody SmartFlag by APOLLO

One Lock Digital Analog - in case of using printed model

CAD/CAM Libraries

Case no. 7

Required components

Scanbody SmartFlag by APOLLO

Multi Titanium Base

Multi Titanium Base multiSHIFT36°

One Lock Digital Analog - in case of using printed model

CAD/CAM Libraries